Imagine standing in a field at midnight. You can barely see the outline of a low, long building before you, but your eyes don’t linger on its shadows, for at its center, a window arches three stories high, brilliantly lit from within, and under that light stands the first tower of a printing press, a fire-engine red behemoth.

Now imagine you’re inside the building, in the pressroom. The reinforced concrete foundation under your feet is four feet thick, resting on steel pilings driven into bedrock, isolated from the rest of the building — all to deaden vibration. The cinder-block walls around you are stuffed with insulation to deaden sound. The air you’re breathing is cooled, its humidity level controlled, and it’s filtered to remove airborne ink.

A bell rings a warning — the press run begins — you feel the heavy sounds of leviathan machinery gathering speed — and as the noise grows your eyes widen as you stare at the pages whipping by.

The power of the press, the power of the words it carries—man, it’s romantic. Still.

Not the romantic type? Well, even a frigid accountant would get excited over the economies of scale achieved by a running press.

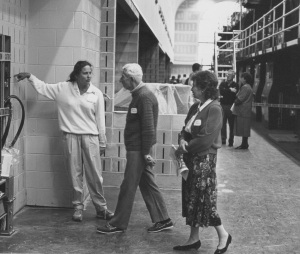

When The Portland Newspapers opened its new production plant in 1989, I was working in the promotion department and was asked to create a special section for company employees. With the help of our department’s graphic artist, I was to explain how the plant and its $15 million Goss Flexoliner presses would work. The section would be distributed on the day the company had set aside for the staff and their families to tour the new plant.

It was a fun assignment; I learned a lot. Most germane to this post, though, is the fact that the new press could produce 70,000 copies an hour.

The cost of putting one edition of a newspaper together—of selling the ad space, reporting and writing the stories, laying it all out—that cost stops going up the moment the edition is ready for the press.

From that point on, the incremental cost per copy begins to go down as the press speeds up. With the exception of paper, ink and power, it costs the same to create 10 copies as it does 100,000. The press spreads the cost of content creation over as many copies as can be sold. The larger the print run, the cheaper each individual copy is to produce. The more papers sold, the more attractive the newspaper is to advertisers. A faster press creates the potential for more revenue at lower per-unit-cost.

When my husband retired, the sports staff of the paper where he’d spent the last 17 years of his career asked him to relate his funniest moment. He wrote:

“The night I drove back to the paper at 2 a.m. to try to stop the presses because I woke up out of sound sleep realizing we’d made a mistake. I was too late. The press crew thought it was hilarious. Little children did not die.”

(The last sentence was a favorite saying, used to reset one’s perspective.)

Of course, had the paper been a digital-only publication, my husband could have walked to the study, turned on the computer, logged in and edited the page. One must admit that web servers achieve awesome economies of scale and reduce distribution costs to nearly zero.

Still, one cannot deny that a well-run press also produces economies of scale — and is romantic, to boot.